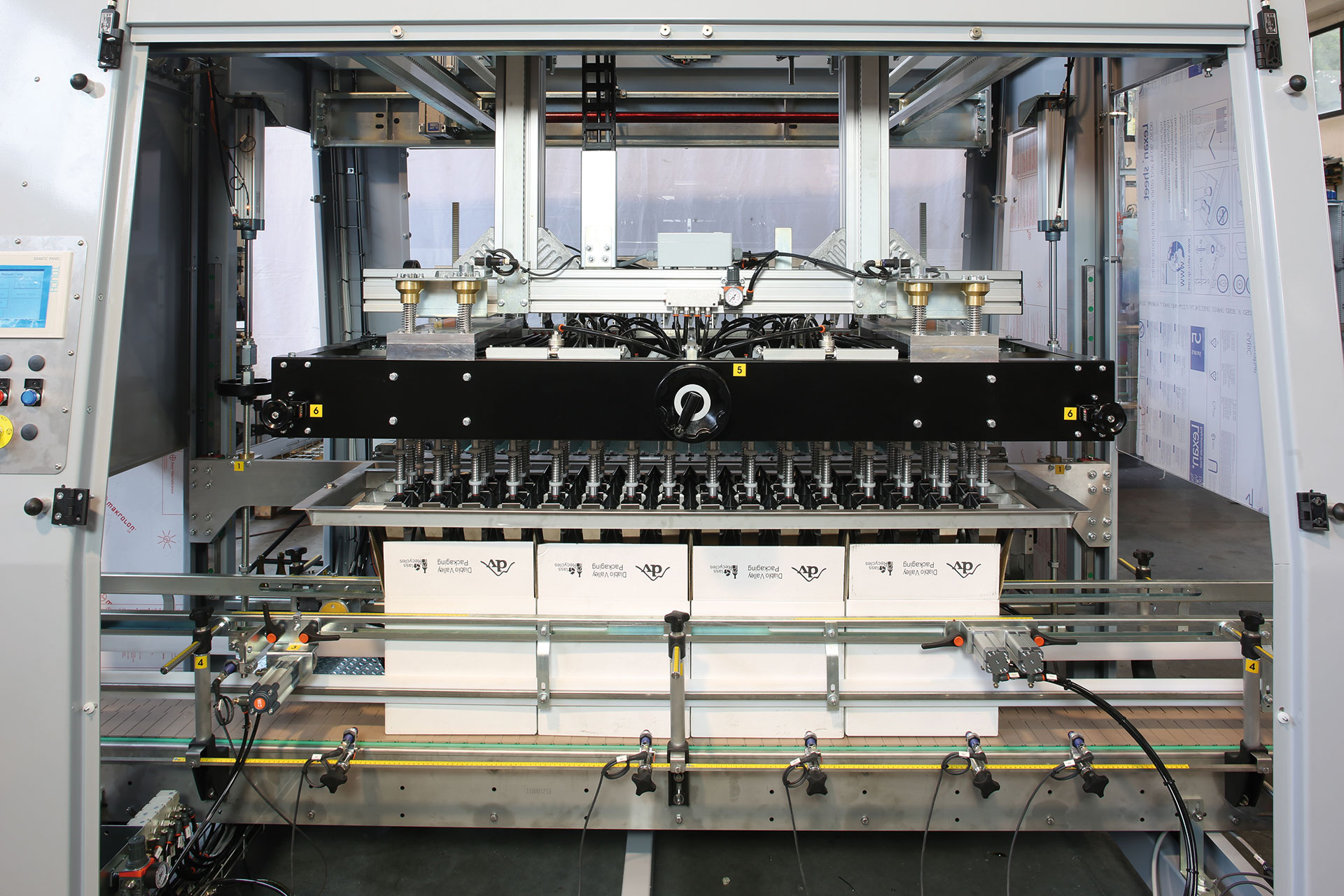

Complete packaging lines and Packaging machines

Tailor-made Packaging lines

In over than 20 years of experience in the packaging world, FIPAL has witnessed the growth of its own reputation, appraisal and customers’ satisfaction.

Pick up the packaging line according to your field

Pick up the packaging line according to your field

Machines packaging lines are composed by

Technology and solutions for every need

Service, Assistance and Innovation

Fipal strenghts

Research and development

Our team of engineers conducts a continuous process of research and development on new technologies available: new mechanical, electronic and IT systems that increasingly improve our quality standards and thus the reliability of our packaging lines and packaging machines.

Sales network

Thanks to our team of highly skilled sales representatives, and to its widespread presence in over than 15 countries across Europe, Asia, Americas and Africa, Fipal has always been able to promptly address customers needs, by providing its expertise and quality in finding the best solution to every issue.

Customer Service

Fipal customer support ensures a highly effective and prompt after-sales service, which enhances and improves the performance and reliability of the installed packaging lines.

Research and development

Our team of engineers conducts a continuous process of research and development on new technologies available: new mechanical, electronic and IT systems that increasingly improve our quality standards and thus the reliability of our packaging lines and packaging machines.

Sales network

Thanks to our team of highly skilled sales representatives, and to its widespread presence in over than 15 countries across Europe, Asia, Americas and Africa, Fipal has always been able to promptly address customers needs, by providing its expertise and quality in finding the best solution to every issue.

Customer Service

Fipal customer support ensures a highly effective and prompt after-sales service, which enhances and improves the performance and reliability of the installed packaging lines.

Industry 4.0

Thanks to the launch of the virtual reality, during design as well as manufacturing phase, FIPAL enables the customer to “actually” see how the line will look like inside the plant and, more importantly, how it will operte.

Case history

Camerons Brewery – Hartlepool, UK

Palletizing and depalletizing line for glass bottles with a 15.000 bph output

PARMALAT – Food dairy company, Collecchio (PR)

Palletizing robot (185 kg payload) equipped with pick&place head

Mionetto Winery – Valdobbiadene (TV), Italy

Complete line for 12.000 bph

FONTE ORSINI – Water source, Poggiorsini (BA)

It has been integrated a bundle palletizer into a 16.000 bph PET Line.

Aston Manor Brewery – Birmingham, UK

Palletizing and depalletizing line for beer aluminium cans for 30.000 cph output

PARMALAT – Food dairy company, Collecchio (PR)

Revamping on the customer’s existing robot, it has been repurposed as robotic palletizing system for products in trays

Fill out the form

Quick response guaranteed!

...or call us

+39 0525 431199

(GTM+2; Italian time)

9,00 > 13,00 | 14,30 > 18,00